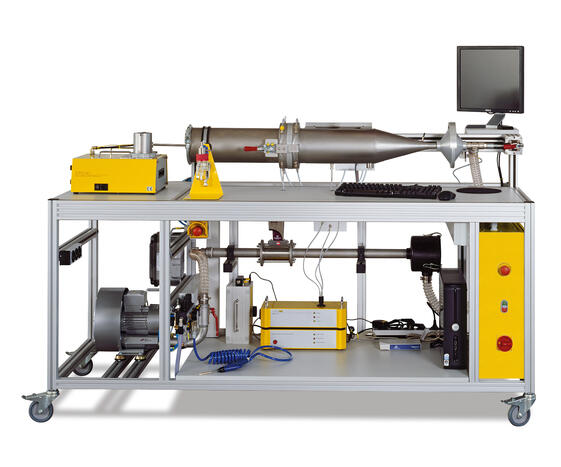

AFC 132 Test System

AFC132 Test System for characterisation of filter media and small filter elements

Important features for characterising filter media are:

- pressure drop depending on flow rate or dust loading,

- fractional efficiency with DEHS and KCl,

- gravimetric arrestance,

- loading capacity.

The AFC 132 can also be used to realise a customised filter media test with individual test conditions and freely configurable sequences.

Standards

download

product sheet AFC 132Benefits

- use of different aerosols possible (solid and liquid aerosols)

- flexible design allows quick modifications and future enhancements

- variable volume flow range

- excellent component matching through combination of Topas devices

- user-friendly AFC132Win data acquisition and test rig control software

Applications

- filter tests on the basis of several standards

- air filter for general ventilation acc. ISO 16890 (Discharging with TDC 585), EN779 and ASHRAE 52.2

- high efficiency filters (EPA, HEPA and ULPA) ISO 29463

- air filters for passenger compartments acc. to DIN 714560-1/ ISO/TS 11155-1

- inlet air cleaning filters for internal combustion engines and compressors according to ISO 5011

- development and optimization of filter media in accordance with internal company standards

- quality assurance during production

- quality inspection of flat filter media as final test during production or as incoming inspection before further processing

The filter medium is clamped in a special filter holder, which guarantees the secure and tight fit of the test object during the test. With a few simple steps, the filter holder is removed from the test channel to change the filter medium or to determine its mass. A support grid prevents strong deformation of the test specimen at high flow rates. The final filter (absolute filter) downstream of the test filter can also be easily installed and removed for mass determination.

The fractional efficiency is determined with an optical particle counter LAP 340 in a particle sizes range of 0,2 to 10,0 µm. The sampling between upstream, downstream and purge is controlled by and sample switching unit SYS 520. This means that only a single particle measuring device is required. The switching time of the sample switching unit SYS 520 is freely adjustable by the user. If required, a Topas dilution system series DIL 55x or an aerosol spectrometer LAP 322 with a particle size range from 0,2 to 40 µm can be supplied.

| Parameter title | Unit | Value |

|---|---|---|

| test flow rate | m³/h | 0,4 ... 40 or 2 ... 64 |

| test aerosol | - | customer-specific (DEHS, paraffin oil, NaCl, PSL, ...) |

| dimension of test specimen | - | diameter ≤ 150 mm |

| operating medium, gas/air | - | conditioned room air suitable for standard tests |

| operating medium, gas/air - compressed air supply | bar | 6 |

| power supply | - | 400 VAC, 16 A |

| environmental condition, temperature | °C | 0 ... 50 |

| environmental condition, relative humidity | % | 0 ... 100 |

| dimensions (w × h × d) | mm | 2100 × 1400 × 850 |

| weight | kg | approx. 300 |