Exhaust emission standards for internal combustion engines are becoming more stringent all the time and, due to reduced activities in the further development of engines, are placing greatly increasing demands on exhaust gas aftertreatment. This applies not only to diesel but also petrol engines. For this reason, the test methodology must be expanded for the exhaust filter systems that have been used in diesel vehicles for decades and are already increasingly being used in petrol engines. On the engine test bench, overall efficiency is always determined with the engine loaded. Increasingly, however, the fractional separation efficiency in the initial unloaded state is also of interest for the application-oriented optimization and quality control of diesel particulate filters (DPFs) and petrol/gasoline particulate filters (GPFs). This requires a rethinking of the measurement strategy.

Driven by our customers and their needs we are developing ourselves in the field of filter testing permanently. See here the latest developments in terms of “100% control in filter testing”.

Overview "Production test systems for fully automated filter testing during production"

Manufacturers of exhaust filters, technology leaders for functionalised coatings and, above all, automotive end users increasingly are requested to do 100% production control instead of random testing in the laboratory. This means that testing of the separation efficiency must be non-destructive.

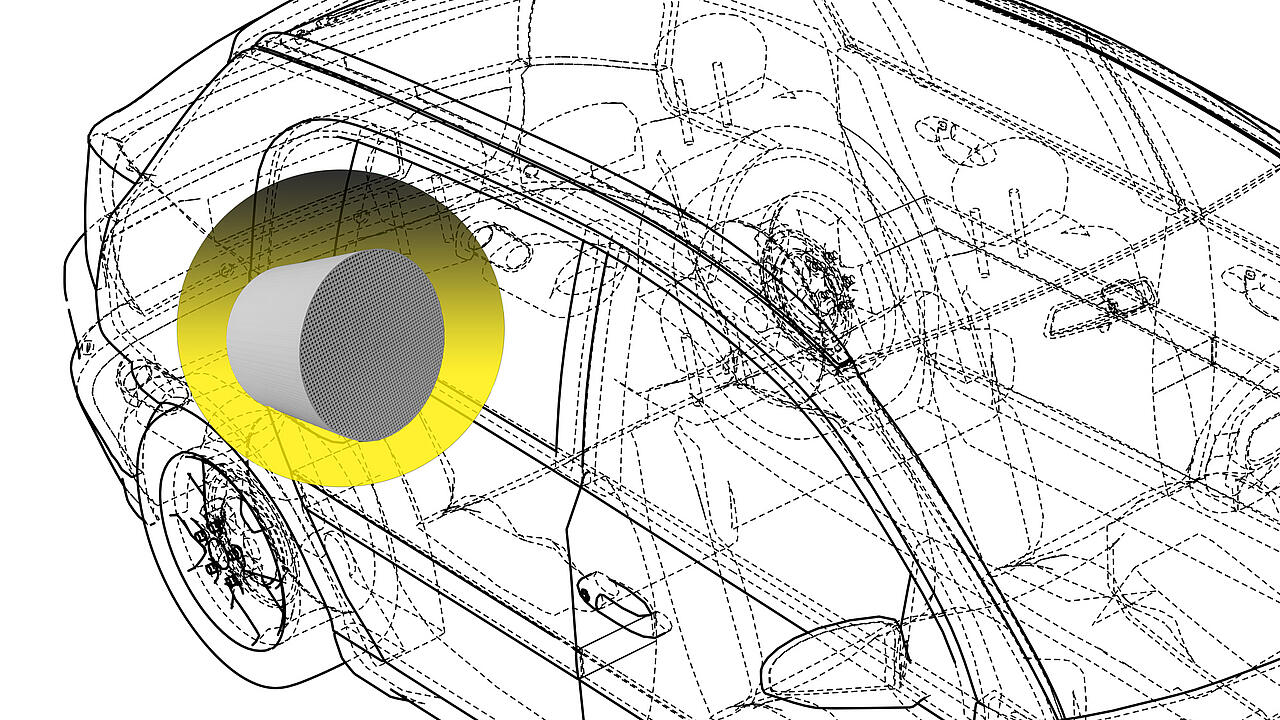

With the launch of the AFC 136, we have succeeded in creating a filter element test rig that meets this requirement without exception and reliably tests petrol and diesel particulate filters.

Testing with the AFC 136 filter element test rig

- 24/7 production test, measurement time of 30s per filter

- Differential pressure determination at nominal volume flow

- Total separation efficiency and fractional separation efficiency

- Particle size range, depending on the measuring technique used

- Applicability for different filter types and dimensions

- Reliable operation of the test system and documentation of the test results

- Automated database integration

Testing can be performed with different reference aerosols, either monodisperse or polydisperse. Various aerosol analytical instruments, such as optical particle counters or condensation particle counters, can be implemented in the test system for raw and clean gas particle measurement. Included is the AFCWin test system control and data acquisition & evaluation software for standard Windows PCs, which provides specified and adaptable test procedures to ensure that the stand is immediately ready for operation, even when the product is changed.

Air filter production testers learned a lot with our customers for this new application area. Especially with the AFC 132 QC HEPA, we have gained a lot of experience in 24/7 availability and, based on this knowledge, have developed the prototype AFC 136 together with reference customers in 2019. Its procedural refinements and innovations expand the range of our production testing systems. We are happy to meet the associated higher demands on service and availability for you.