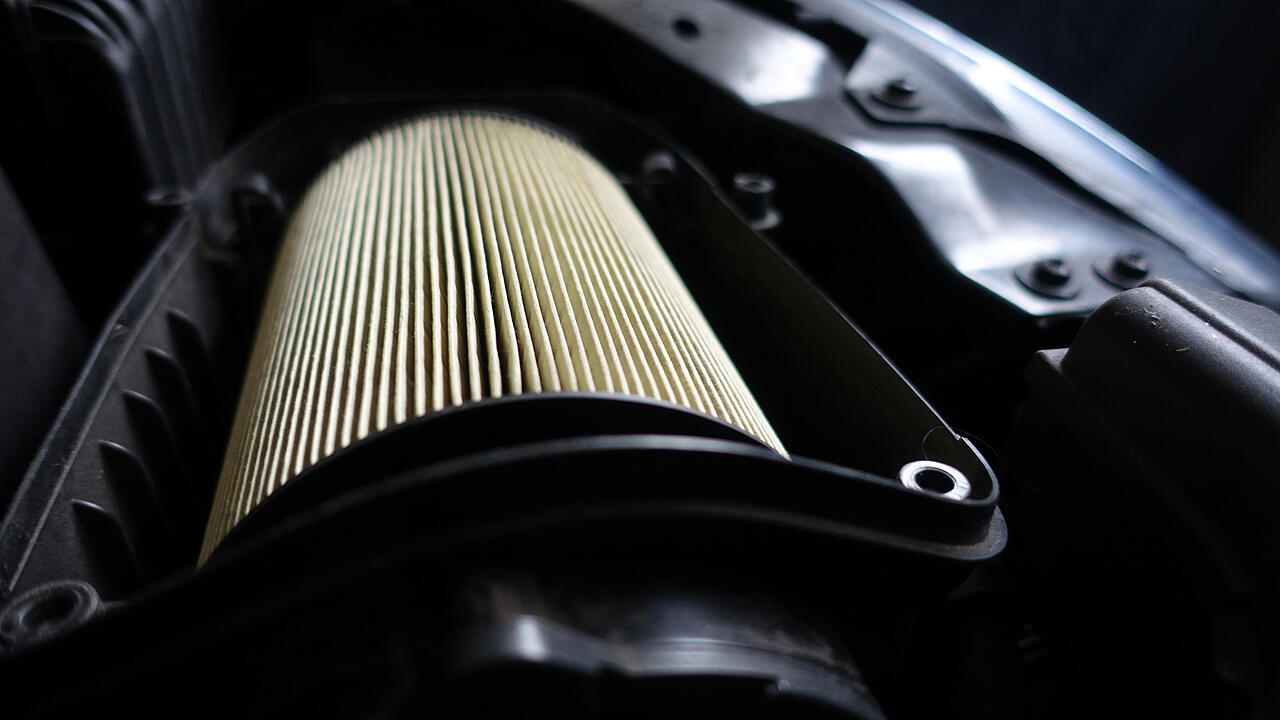

On the one hand, engine intake filters protect the engine and its components from wear caused by coarse solid particles and, in general, also contribute to the overall emissions balance of motor vehicles such as two-wheelers, cars, trucks or construction machinery. After all, dust and sand are the enemies of any combustion engine, whose intake filters are deigned to capture these pollutant particles. Our testing technologies reliably prove that engine intake filters do this and comply with current standards. In doing so, our test systems are capable of testing separation media, filter elements and even complete filter assemblies. And don’t forget: ISO 5011 also applies to intake filters of machines and systems, which our technologies can also reliably test. When it comes to protecting fuel cells from harmful gases such as NOx or So2, adsorption filters are in demand. For these, we offer customer-specific gas metering systems to provide special test gases.

Testing the separation efficiency of intake air filters for fuel cells

The FCT 113, our first Fuel Cell Air Intake Filter Test System, enables molecular efficiency testing for cathode air filters. It is a further development of our first test system, the established PAF 112 cabin air filter test bench and enables our clients to test with various gases (O3, SO2, NO2, toluene) at a wide flow rate range of 18 to 800 m3/h. We keep a close eye on trends in the automotive sector and put years of expertise into the development of the traditional test system – a promise of quality to our customers.

Do you have any questions? Write to us. Climate-friendly mobility is (still) a challenge, but testing the necessary supply air filters with FCT 113 technology will soon be an easy task.

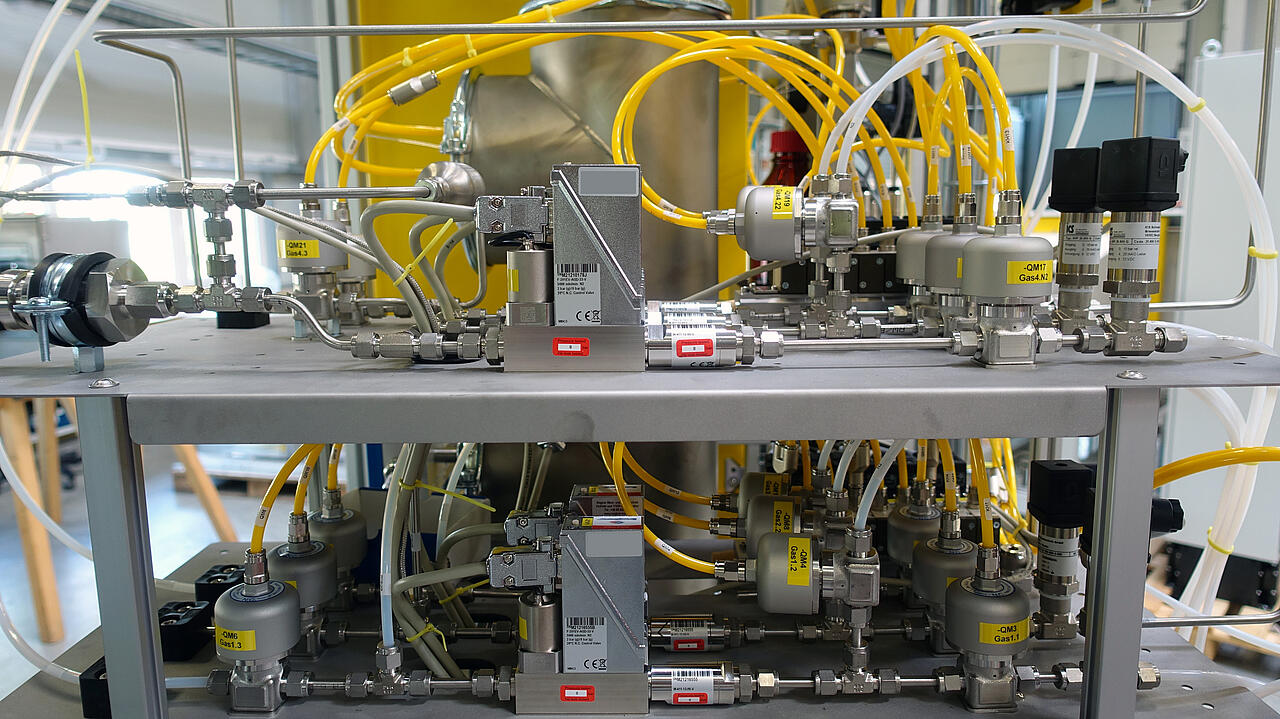

The various components of the PAF 112, which has been an established adsorption test rig for cabin interior filters for decades, can be used to provide metering gases for testing supply air adsorption filters for fuel cells:

- MFC 594 Mass Flow Gas controller & converter (NH3, H2S)

- LGC 595 Liquid Dosing Gas Controller (Toluene, Ethylacetate)

- EGC 596 Evaporation Gas Controller (Acetaldehyde)

- MGC 597 Mixing gas controller (NO2/NOx)

More time for your other responsibilities: take advantage of the high level of automation in Topas test systems.

With the ABP 115 engine intake filter test system, the following test routines can be used for evaluating particle separation according to ISO 5011 or according to your customer-specific factory standards.

- Differential pressure test

- Testing the gravimetric separation efficiency

- Dust load capacity

In addition to the normative requirements, water injection is also possible to assess water resistance and separation in the test specimen.

The SAG 420 dust disperser is implemented in the test system for dust metering and dispersing. It offers the advantage of being adaptable to the height of the test specimen with an adjustable frame according to customer specifications. The integration of a scale into the control system allows gravimetric dust feeding in a closed control loop. Further dust dosing systems of the SAG series can also be flexibly integrated into your existing test stands.