Our strength is based on years of practical experience

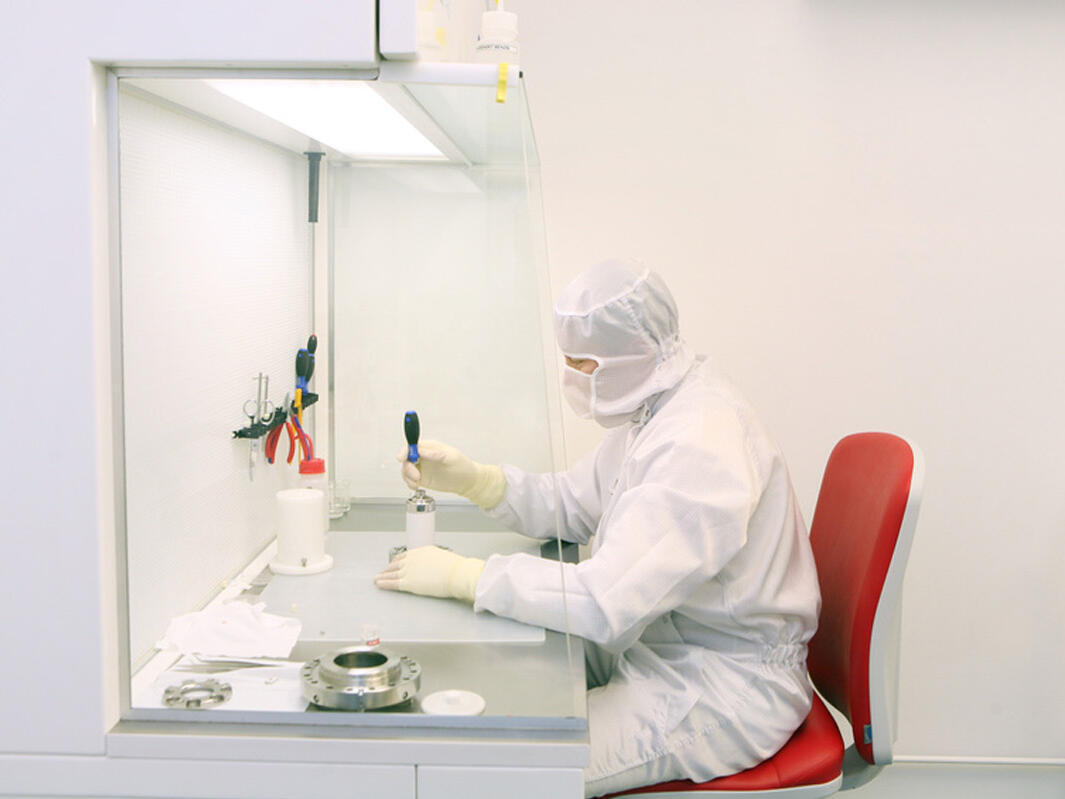

Your focus is on the highest level of precision, because you work in a cleanroom and are responsible for quality assurance there? We know that the regular testing of air filters, the certification of safety cabinets or cleanroom acceptance measurements can only be managed with technology you can trust one hundred percent.

Topas devices test air filters in their installed state, whether they are complete ceiling filters or safety cabinets confined to a limited space. The operators of cleanrooms und ultra-cleanrooms depend on documented proof of compliance with defined limit values. To provide this, national and international authorities, as well as cleanroom operators and validation service providers from a wide range of industries turn to us:

- microelectronics

- pharmaceutical industry

- medical technology

- nuclear industry

- food industry

- aerospace industry

To ensure the highest product quality, cleanroom systems are being used with increased frequency. These systems have to be checked regularly to ensure that they are in good working order. In addition to expertise, the inspector needs appropriate technical equipment that is sufficiently safe and complies with the relevant standards and guidelines (VDI 2083, VDI 3867, DIN EN 12469, DIN 12980, ANSI IEST ISO 14644, ISO 21501). As a leading manufacturer of these devices, Topas offers an extensive and high-quality product range for acceptance measurements of cleanrooms, the use of which is explained in more detail in the topics listed here. Special emphasis was placed on ensuring the suitability of the testing technology for mobile use.

Since the early days, Topas has been a proven technology leader in this field: in more than 45 countries with more than 1000 customers. There are now more than 5000 aerosol generators and dilution systems in satisfied customer hands, making these our most important series equipment applications for decades. Also in the future we will continue to live up to the high standards we have set for ourselves and keep our focus in this field.

CFG 291

Condensation Fog Generator CFG 291 for fog generation to visualise air flows according to ISO 14644-3

ASH 048

Antistatic hose for optimal sampling and aerosol transport, inner diameter 4,8 mm (0,19''), flexible

ASH 079

Antistatic hose for optimal sampling and aerosol transport, inner diameter 7,9 mm, flexible

ATM 226

ATM 226 Atomizer Aerosol Generator for aerosol generation from liquids for mobile use (e.g. cleanroom acceptance measurement), integrated compressor

ATM 228

Atomizer Aerosol Generator ATM 228 for aerosol generation from liquids for mobile use, integrated compressor, pneumitic-controlled, remote controllable

ATM 230

Atomizer Aerosol Generator ATM 230 for aerosol generation from liquids, compressed air operated, high mass flow rate

ATM 241

Atomizer Aerosol Generator ATM 241 for aerosol generation from liquids, compressed air operated, very high mass flow rates, operation with 1 to 4 nozzles

DEHS

Liquid aerosol substance DEHS for operation with aerosol generators of the series ATM

DIL 554

DIL 554 Dilution System for static dilution (1:100) of aerosols at static air flow rate (28,3 L/min) for mobile operation

DIL 554/H

DIL 554/H Dilution System for static dilution (1:100) of aerosols at static air flow rate (56,6 L/min) for mobile operation

DIL 554/T

DIL 554/T Dilution System for static dilution (1:100) of aerosols at static air flow rate (28,3 L/min) for mobile operation, 1/4'' hose connector

DIL 554/Z

DIL 554/Z Dilution System for static dilution (1:10) of aerosols at static air flow rate (28,3 L/min) for mobile operation

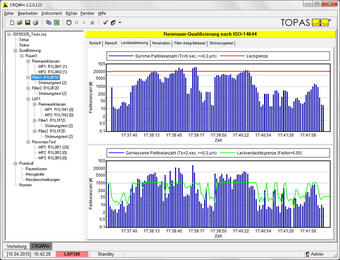

LAP 340

Optical Particle Counter LAP 340 for analysis of particle size distributions and particle concentrations in aerosols, best for cleanroom applications

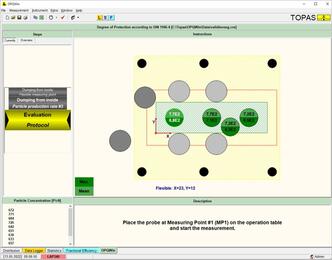

OPQWin

OPQ-Win software for acceptance testing of operating theatres according to DIN 1946-4

SYS 528

Rectangular Sampling Probe SYS 528 for leakage and integrity testing according ISO 14644-3 for a sample flow rate of 50 l/min

SYS 529

Rectangular Sampling Probe SYS 529 for leakage and integrity testing according ISO 14644-3 for a sample flow rate of 28,3 l/min

TopFog Light

Fog fluid TopFog Light for operation of the Condensation Fog Generator CFG 291

VDS 562

Variable Dilution System VDS 562 for variable adjustable, pressure drop compensated dilution of aerols at defined air flow rates