Oil-bearing blow-by gas from the crankcase is one of the factors that significantly influence the emission behaviour of vehicles (EURO standard). Excessive oil loss also damages the engine. Since the separation efficiency of oil mist separators depends on the operating point of the engine, this results in a correspondingly complex characteristic map. The established gravimetric approach to characterizing oil mist emissions provides only a very low resolution of this map due the long measurement times necessary. Consequently, this leads to high costs for the use of engine test benches.

With the robust optical inline measurement technology developed by Topas, complete maps of crankcase emissions can be measured in less than one day with significantly improved resolution by cleverly combining the optical inline measurement with an application-optimized gravimetric approach.

Meet the high requirements of oil mist separators with an optimum solution using our blow-by-separator test system

With the selection of a suitable separator for a particular engine, your goal is to minimize the blow-by oil content and thus to reduce emissions and protect many essential parts of the crankcase and engine. As a manufacturer of oil mist separators, or as an engine or passenger car manufacturer, you know that while engine development is stagnating, at least in the passenger car sector, exhaust emission standards are becoming more stringent. This is why a high degree of separation is demanded of oil mist separators today, which can often only be achieved with active separators. Our test systems make valid statements about the content in crankcase gases. This means that separators can be selected and optimized to suit the application. Our technology also contributes to the improvement of all filters in the engine air stream (intake, blow-by and exhaust filters).

Testing under laboratory conditions with the SPT 140 oil mist separator test system

The SPT 140 is used to validate oil mist separators in the laboratory under simulated operating conditions prior to installation. To do this, the SPT 140 simulates the engine as a reference system and enables the following test procedures:

- Total separation efficiency (gravimetric)

- Flow curve (pressure drop versus volume flow)

- Pressure control curve

- Leakage volume flow

- Oil mass flow rate (g/h)

- Oil concentration (g/m³)

The LDG 244 oil droplet generator for large oil droplets is implemented in the test system to simulate wall film and surge oil effects. The core of the test rig is the ATM 243 aerosol generator, which was specifically developed for testing oil mist separators.

Three innovative Topas technologies combined in one measuring system

- Gravimetric measurements with the GMS 141 Gravimetric Measuring System

- Optical concentration measurements with the PAP 610 Process Aerosol Photometer

- Detection of oil films in lines and surge oil, e.g., on swing test rings with the compact PAP 612 Process Aerosol Photometer

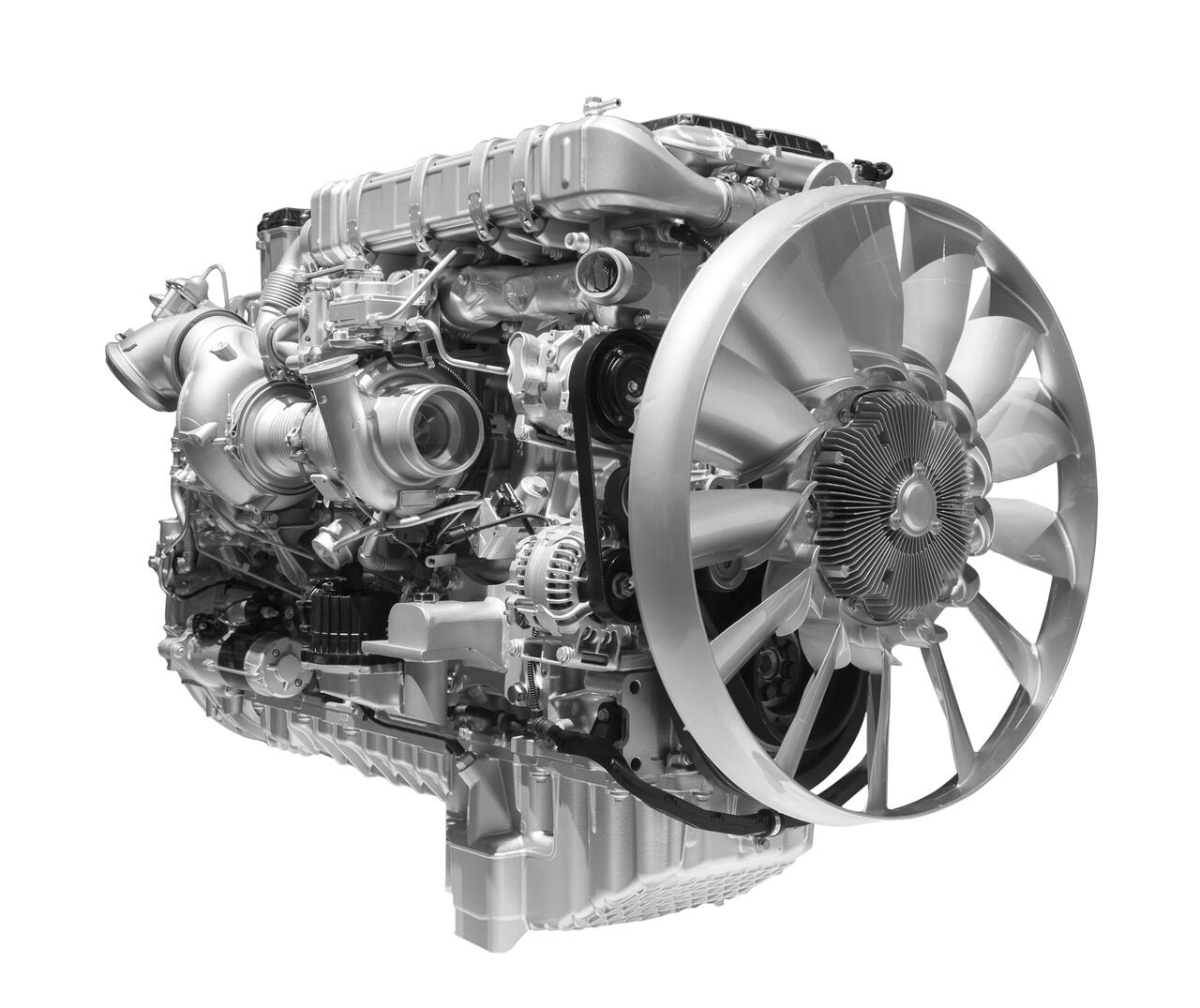

Testing on the engine test bench with the BBT 143 blow-by test system

The BBT 143 transportable measuring system is used to validate oil mist separators directly on the running engine under realistic conditions. The test method records the oil mass flow and can be fully integrated into the engine test bench in terms of control and measurement data acquisition. The following evaluations can be performed:

- Determination of the oil content in the blow-by on the engine test bench

- Blow-by volume flow measurement (l/min)

- Oil mass flow determination (g/h)

- Oil concentration (g/m³)

- Evaluation of oil mist separators on the engine test bench

- In-line detection of wall films and surge oil

- Our blow-by test stand BBT 143 is the result of a joint project with a world-leading automotive manufacturer and a global filter manufacturer. It is now in use at almost all major international automotive and oil mist separator manufacturers.

-

New environmentally friendly drive concepts with hydrogen appear to have a promising future if its production can be ensured using renewable energies. Our aim is to transfer proven measurement technology to new concepts, adapt the accuracy of our measuring devices and thus respond to changing legal requirements. We develop test systems for fuel cell filters for our customers and keep our finger on the pulse.