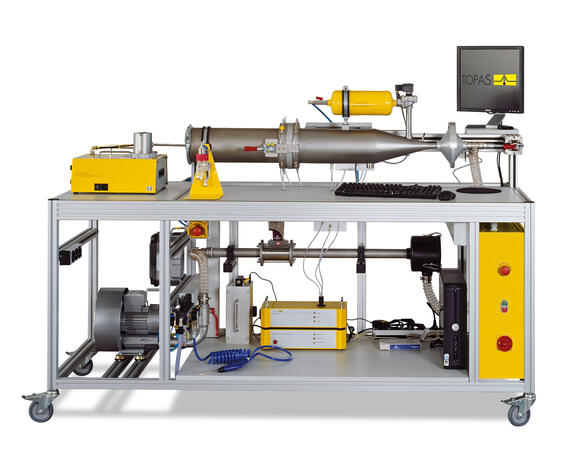

AFC 131 Test System

AFC 131 Test System for characterisation of cleanable filter media acc. VDI 3926-2

Testing of filter media is important for the development and optimisation of filter materials as well as for quality assurance during the production process.

Most interesting parameters for filter media characterisation are:

- differential pressure drop

- gravimetric separation efficiency

- particle size dependent filtration efficiency

- dust loading capacity

For these tasks Topas developed the AFC 131 Filter Media Test System which facilitates filter tests in accordance with guideline VDI 3926 exemplary embodiment 2 and ASTM D6830-02, but can also be used for other tests. Separation efficiency and dust loading tests on basis of the general requirements of ISO 16890, EN 779, DIN 71460-1, ISO/TS 11155-1 and ISO 5011 can be performed in small scale.Due to its compact and lightweight design this test rig can be used in the laboratory.

- differential pressure drop

- gravimetric separation efficiency

- particle size dependent filtration efficiency

- dust loading capacity

For these tasks Topas developed the AFC 131 Filter Media Test System which facilitates filter tests in accordance with guideline VDI 3926 exemplary embodiment 2 and ASTM D6830-02, but can also be used for other tests. Separation efficiency and dust loading tests on basis of the general requirements of ISO 16890, EN 779, DIN 71460-1, ISO/TS 11155-1 and ISO 5011 can be performed in small scale.Due to its compact and lightweight design this test rig can be used in the laboratory.

Standards

VDI 3926-2

download

product sheet AFC 131Benefits

- standardised filter testing with alumina oxide (e.g.: Pural NF)

- automated testing procedure over 14 hours without intervention by operator

- use of different aerosols possible (solid and droplet aerosols)

- flexible design enables fast modification and future addons

- operatir-friendly control software PAFWin

Applications

- filter tests for cleanable filter according to VDI 3926-2

- determination of fractional separation efficiency, dust loading capacity and differential pressure drop of filter media

- filter tests based on other standards (air cleaning filters ISO 16890, EN 779; cabin air filters ISO 11155-1)

- development and optimisation of filter media

- quality assurance measurements

| Parameter title | Unit | Value |

|---|---|---|

| test flow rate | m³/h | 2 ... 64 |

| measuring range, differential pressure | Pa | |

| duration of pressure pulse | ms | 50 ... 150 |

| pressure tank capacity | bar | 2 ... 6 |

| dimension of test specimen | mm | diameter ≤ 150 |

| power supply | - | 3 × 400 V AC, 16 A |

| operating medium, aerosol substance | - | Pural-NF, Pural-SB, DEHS |

| sensors, others | - | temperature, relative humidity |

| dimensions (w × h × d) | mm | 2800 × 1500 × 800 |

| weight | kg | approx. 120 |

- Atomizer Aerosol Generator ATM 220

- Solid materials disperser SAG 410

- Aerosol Dilution System DIL 550

- Aerosol Spectrometer LAP 322

- Xiong F., Wang X., Liu Y., Zhang Z., Zhang T., Gao H., Fu H., Huang J., Qian X., Lai Y. and Zhang S. Sandwich structured chitosan-aerogel nonwoven filter with asymmetric wettability and pore size differences for high-efficient oil-mist filtration J. Environ. Chem. Eng. 11 (2023) 5, 110443

dx.doi.org/10.1016/j.jece.2023.110443 - Fan Q., Liang W., Fan T.-T., Li X., Yan S.-Y., Yu M., Ning X. and Long Y.-Z Polyvinylidene fluoride composite nanofibrous filter for high-efficiency PM2.5 capture Composites Communications 22 (2020) 100533,

dx.doi.org/10.1016/j.coco.2020.100533 - Li T.-T., Fan Y., Cen X., Wang Y., Shiu B.-C., Ren H.-T., Peng H.-K., Jiang Q., Lou C.-W. and Lin J.-H. Polypropylene/Polyvinyl Alcohol/Metal-Organic Framework-Based Melt-Blown Electrospun Composite Membranes for Highly Efficient Filtration of PM2.5 Nanomaterials 10 (2020) 10,

dx.doi.org/10.3390/nano10102025 - Liu Y., Qian X., Wang L., Qian Y., Bai H. and Wang X. Hierarchical micro/nanofibrous filter for effective fine-particle capture Powder Technology 360 (2020) 0, 1192 - 1199

dx.doi.org/10.1016/j.powtec.2019.11.012 - Liu Y., Qian X., Zhang H., Wang L., Zou C. and Cui Y. Preparing micro/nano-fibrous filters for effective PM 2.5 under low filtration resistance Chem. Eng. Sci. 217 (2020) 115523,

dx.doi.org/10.1016/j.ces.2020.115523 - Wang Z., Yan F., Pei H., Yan K., Cui Z., He B., Fang K. and Li J. Environmentally-friendly halloysite nanotubes@chitosan/polyvinyl alcohol/non-woven fabric hybrid membranes with a uniform hierarchical porous structure for air filtration Journal of Membran Science 594 (2020) 117445,

dx.doi.org/10.1016/j.memsci.2019.117445 - Yang Y., He R., Cheng Y. and Wang N. Multilayer-structured fibrous membrane with directionalmoisture transportability and thermal radiation forhigh-performance airfiltration e-Polymers 20 (2020) 1, 282 - 291

dx.doi.org/10.1515/epoly-2020-0034 - Zhu F., Su J., Wang M., Hussain M., Yu B. and Han J. Study on dual-monomer melt-grafted poly(lactic acid) compatibilized poly(lactic acid)/polyamide 11 blends and toughened melt-blown nonwovens Journal of Industrial Textiles 49 (2020) 6, 748 - 772

dx.doi.org/10.1177/1528083718795913 - Li X., Wang X.-X., Yue T.-T., Xu Y., Zhao M.-L., Yu M., Ramakrishna S. and Long Y.-Z. Waterproof-breathable PTFE nano- and Microfiber Membrane as High Efficiency PM2.5 Filter Polymers 11 (2019) 4,

dx.doi.org/10.3390/polym11040590 - Li T.-T., Cen X., Ren H.-T., Sun F., Lin Q., Lou C.-W. and Lin J.-H. One-Step Bark-Like Imitated Polypropylene (PP)/Polycarbonate (PC) Nanofibrous Meltblown Membrane for Efficient Particulate Matter Removal Polymers 11 (2019) 8,

dx.doi.org/10.3390/polym11081307 - Zhu F., Su J., Zhao Y., Hussain M., Yasin S., Yu B. and Han J. Influence of halloysite nanotubes on poly(lactic acid) melt-blown nonwovens compatibilized by dual-monomer melt-grafted poly(lactic acid) Text. Res. J. 89 (2019) 0, 4173 - 4185

dx.doi.org/10.1177/0040517519826926 - Yao L.-R., Song X.-M., Zhang G.-Y., Xu S.-Q., Jiang Y.-Q., Cheng D.-H. and Lu Y.-H Preparation of Ag/HBP/PAN Nanofiber Web and Its Antimicrobial and Filtration Property Journal of Nanomaterials 0 (2016) 4515769,

dx.doi.org/10.1155/2016/4515769