DDS 560 Dilution System

Dynamic Dilution System DDS 560 for variable-adjustable dilution of aerosols at variable air flow rates

Optical particle counters show a maximum measurable aerosol concentration due to their operating principle. If this limit is exceeded major errors cannot be excluded, for example because of coincidence. In case of clean room testing or laminar flow box testing according to VDI 2083 measurements of high upstream concentrations are required. Conventional clean room particle counters are unable to measure at such high concentrations.

By placing the dynamic dilutor DDS 560 before a particle measuring device, e.g. the LAP 322: Laser Aerosol Particle Size Spectrometer, the aerosol concentration can be reduced by a factor selected by the user. Thus, the required upstream concentration can be diluted to a concentration which is within the measuring range of the particle counting device.

Standards

download

product sheet DDS 560Benefits

- infinitely variable dilution of aerosols

- infinitely variable sample flow

- monitoring and visualisation of sample flow and dilution ratio

- characteristics of the gas phase of the aerosol (e.g. humidity) are maintained

- self-contained system (i.e., no external air supply necessary, no exhaust air flow)

Applications

- validation and test of clean room equipment

- checking HEPA- and ULPA-filters

- filter media verification

- aerosol research

- verification of aerosol generators and powder disperser

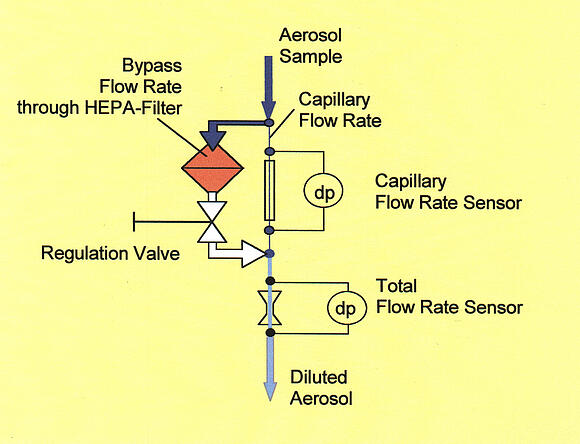

The operating principle is based on the splitting of the total volume flow into a so-called bypass volume flow and a capillary volume flow. By means of an HEPA-filter all the particles are removed from the substantially larger bypass volume stream. The particle concentration of the smaller capillary volume stream remains unchanged. These two flows are eventually brought together again. The dilution factor is determined by the ratio of the capillary volume flow to the total volume flow. Both volume flow rates are continuously measured. The volume flow ratio is calculated and shown on the display. The total flow rate of the DDS 560 is set by the inlet volume flow of the particle counter. The user can adjust the desired dilution ratio with a control valve in the bypass line.

| Parameter title | Unit | Value |

|---|---|---|

| purpose of conditioning | - | dilution of aerosols |

| sample condition, outlet | - | diluted aerosol |

| setting parameter | - | dilution factor |

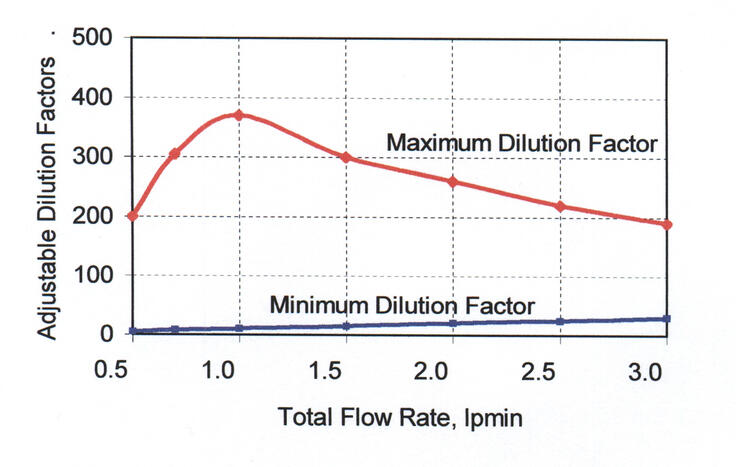

| setting range | - | 5 ... 370 (depending on aerosol flow rate, see product sheet) |

| setting resolution | - | 1 |

| setting method | - | manual |

| aerosol, volumetric flow rate | L/min | 0,5 ... 3,0 (continously variable) |

| sample condition, inlet | - | non-diluted aerosol |

| power supply | - | 12 V DC, 300 mA (via power adapter) |

| hose connector | mm | Ø 8 (outer diameter) |

| material, capillary | - | brass |

| environmental condition, max. counterpressure | kPa | ± 35 |

| dimensions (w × h × d) | mm | 300 × 200 × 140 |

| weight | kg | 2,9 |

- set of straight adapter R3 and elbow adapter R4 for aerosol outlet

- replacement HEPA-Filter capsule

-

Göhler D., Aslanyan L., Oelschlägel K., Bucur P., Buggisch J., Azhari N., Rudolph A., Roger S., Stintz M., Bausch D., Demtröder C., Ouaissi M. and Giger-Pabst U. Performance of intraoperative surgical smoke management technologies for laparoscopic surgery: A comparative in-vivo pig study J. Aerosol Sci. 177 (2024) 0, 106309

dx.doi.org/10.1016/j.jaerosci.2023.106309 -

Kretzschmar, B.S.M.; Bergelt, P.; Göhler, D.; Firmbach, F.; Köcher, R.; Heft, A.; Stintz, M. & Grünler, B. Modulation of silica layer properties by varying the granulometric state of tetraethyl orthosilicate precursor aerosols during combustion chemical vapour deposition (CCVD) Aerosol Sci. Technol. 54 (2020) 10, 1124 - 1134

dx.doi.org/10.1080/02786826.2020.1762845 -

Tran S., Iida K., Yashiro K., Murashima Y., Sakurai H. and Olfert J. S. Determining the cutoff diameter and counting efficiency of optical particle counters with an aerodynamic aerosol classifier and an inkjet aerosol generator Aerosol Sci. Technol. 54 (2020) 11, 1335 - 1344

dx.doi.org/10.1080/02786826.2020.1777252 -

Göhler D., Stintz M. Granulometric characterization of airborne particulate release during spray application of nanoparticle-doped coatings. Journal of Nanoparticle Research 16 (2014) 2520,

dx.doi.org/10.1007/s11051-014-2520-1 -

Mittmann-Frank M., Berger H., Rupf S., Wennemuth G., Pospiech P., Hannig M. and Buchter A. Exposition gegenüber Nanopartikeln und neuen Materialien in der Zahnheilkunde Zentralblatt für Arbeitsmedizin, Arbeitsschutz und Ergonomie 61 (2011) 0, 40-53

dx.doi.org/10.1007/BF03344980