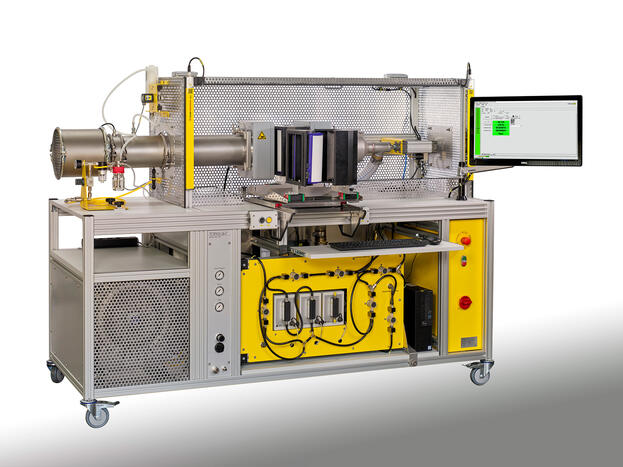

AFC 132 QC HEPA Test System

AFC 132 QC HEPA Test System for quality control during production of small HEPA filter elements

This air filter test system is designed to meet requirements of EN1822-4 and ISO 29463-4, Appendix E “efficiency leakage test for particle sizes from 0.3 µm to 0.5 µm”.

This part of the standard is related to filter elements which cannot be scanned due to their geometrical design. In this case determination of integral filtration efficiency is sufficient for quality control.

Standards

EN 1822-3

EN 1822-4

ISO 29463-3

ISO 29463-4

download

product sheet AFC 132 QC HEPABenefits

- free configuration of target filter efficiency

- customized filter adapter for different small HEPA filter elements, easy to change (5 min)

- compact test system design

- high degree of automation for minimum operator interactions

- designed for 24/7 production operation

- fast cycle time (30 s) for short test time per filter

In comparison to the alternative oil thread test procedure this method gives much more reliable and much faster results on defective filter elements. Furthermore filters are much less loaded by test aerosol from the test procedure.

The required test aerosol is produced by a special aerosol generator (ATM 221) using standard DEHS test liquid. For upstream concentration measurement an optical particle counter is used in combination with cascaded self-adjusting dilution systems (DIL 540/C). A parallel optical particle counter determines downstream particle number concentration. Resulting filter efficiency is compared to nominal filter efficiency giving a final “pass” or “fail” result to each tested filter.

| Parameter title | Unit | Value |

|---|---|---|

| test flow rate | m³/h | 25 ... 130 |

| test cycle duration | s | 30 |

| measuring range, differential pressure | Pa | 0 .... 3000 (± 1 % final value) |

| dimension of test specimen | mm | max. 300 × 300 × 300 |

| power supply | - | 3 x 400 VAC, 50/60 Hz, 16 A |

| operating medium, aerosol substance | - | customer-specific (DEHS, paraffin oil, NaCl, ...) |

| particle measurement instruments | - | particle counter ( 4 channels or 8 channels) with vacuum pump |

| sensors, others | - | temperature, relative humidity, air pressure |

| dimensions (w × h × d) | mm | 2000 × 1500 × 1000 |

| weight | kg | approx. 600 |