The background of our employee at the point of connection between engineering fields, electrical assembly, and series device construction is just as varied as his daily tasks. After a stay abroad in the USA instead of completing his A-levels, years of self-employment in system catering and a subsequent managerial position at Saxony’s largest music store, Daniel Pospiech wanted to go in a new direction in 2017. Career changers are welcome at Topas – and that gave him the chance to enter and advance in the niche industry. Parallel to his employment, he completed an IHK qualification as retail salesman, which made him a good fit in his expanded field of work. In addition to his work, he is currently investing time in further training to become a state-certified electrical engineer specializing in information and communications technology.

A mechatronics technician’s “trade”

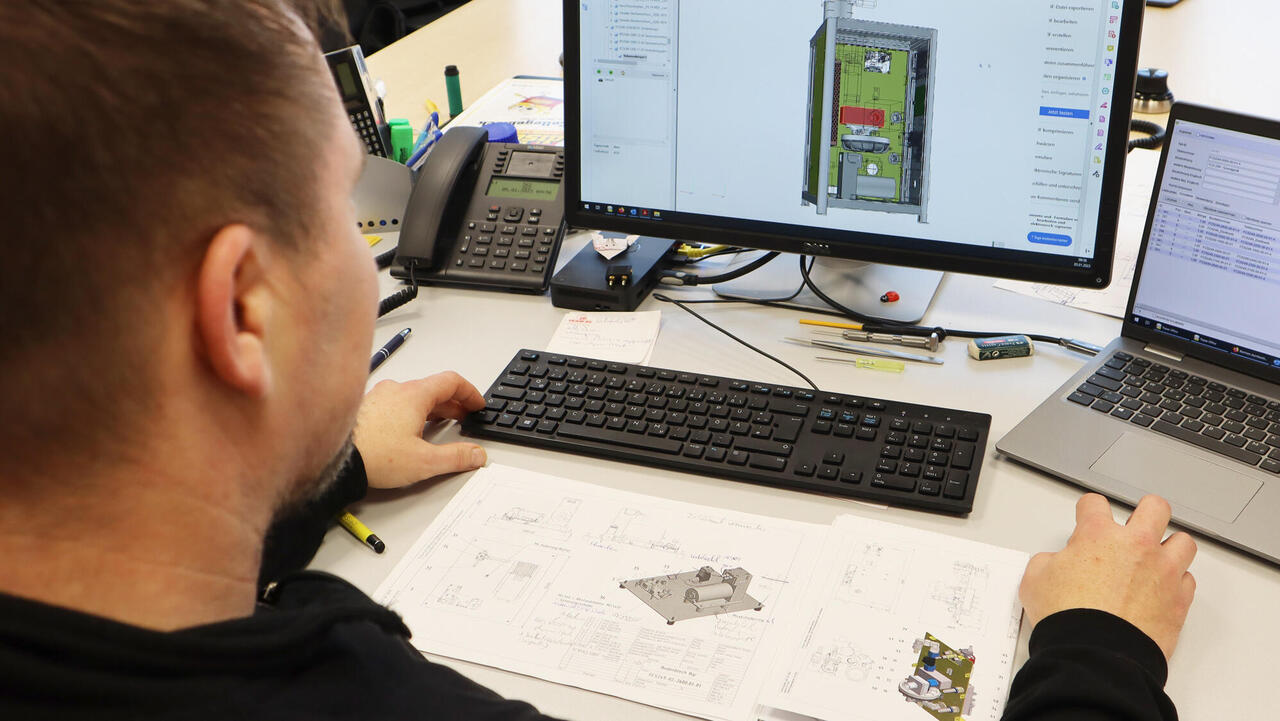

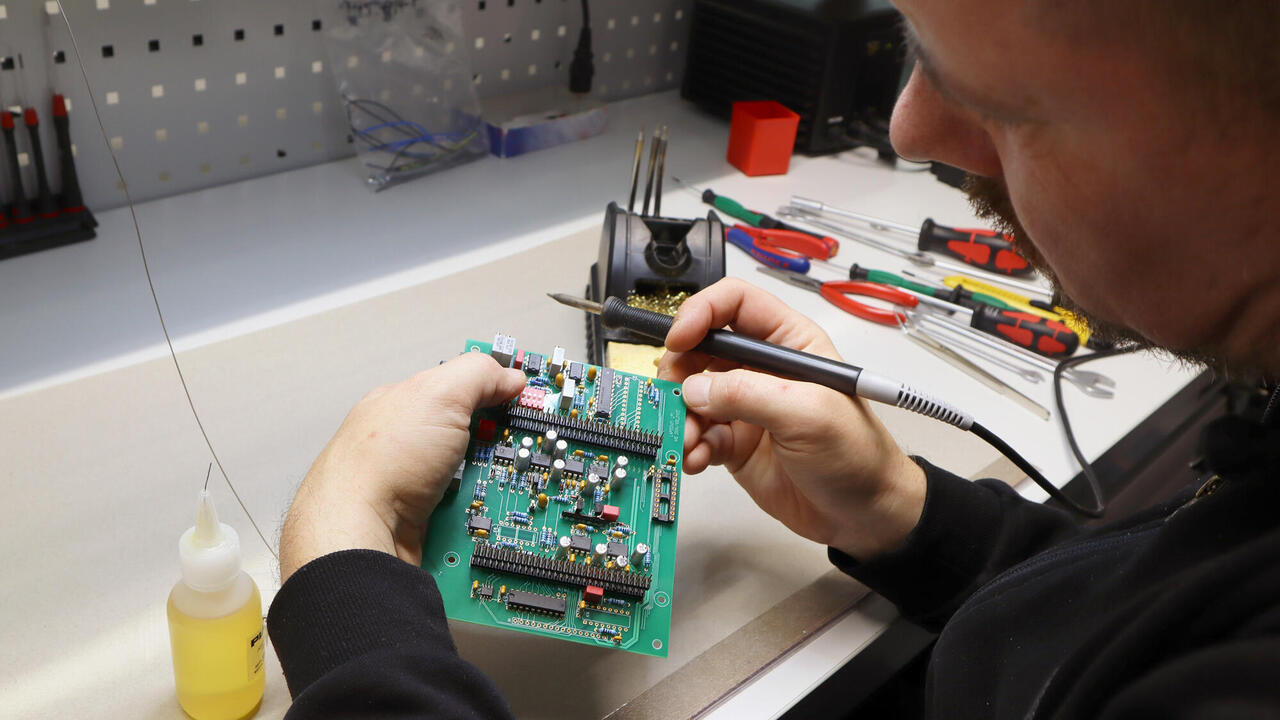

Mechatronics is a discipline in the interface between the fields of mechanics and electronics, as well as computer science. Mechatronics technicians work in mechanical engineering, electrical engineering, or information technology, among other fields. When asked about key qualifications for mechatronics technicians, today’s interface employee cites accuracy, manual dexterity, good knowledge of materials and tools, and requirement to be comfortable with a degree of routine in tasks such as assembling circuit boards for series devices. A mechatronics technician at Topas assembles and repairs, but the daily schedule also includes equipping controllers, motor drivers or displays. For example, firmware for displays or motor drivers must be loaded onto microcontrollers. Soldering irons and multimeters are daily tools of the trade in the electrical workshop, as are drill stands, screwdrivers, or open-end and socket wrenches. High-quality tools, which the mechatronics and electronics technicians at Topas receive according to their needs, bright and functional workrooms in series production, and a modern production hall are also essential conditions for pleasant, efficient work as the basis for the high-quality and precise technologies of the medium-sized company. A certain sensitivity to high electrical voltage on tools or equipment and, if necessary, protective goggles and work shoes are the foreseeable precautions required of Topas mechatronics and electronics technicians.

Exciting opportunities for advancement, also in the interface

From employee to assistant team manager in series equipment manufacturing, Daniel Pospiech continued in the engineering area for series equipment and test systems from 2022. Additional skills were in demand. Pospiech speaks of self-organization and a great interest in standards and guidelines as well as the entire product spectrum. Structured work, the ability to work in a team and good networking within the company are also part of the job. Above all, series equipment manufacturing, research and development, and marketing and sales are departments with which he is in close contact. The interface employee accompanies the development of new devices, manufactures prototypes himself and is the author of manuals and hazard analyses.

Due to his first job in series equipment manufacturing as well as the next one at the engineering level, the retail salesman knows processes and tasks from his own experience and can make comparisons well. At Topas, series devices are usually produced in batches, which allows the mechatronics and electronics engineers to work flexibly. But also when installing devices in test stands, adherence to schedules is required, also with regard to upcoming calibrations. These complex test systems, on the other hand, require more comprehensive documentation and more flexible working methods, because supply chain bottlenecks, among other things, increasingly demand a fragmented approach to work. His knowledge of several departments and positions is in great demand due to the considerable company growth and the associated constant structural adjustments, and interface employees such as himself are becoming increasingly important.

Variety in work and free time as the biggest driver

Thanks to his own drive, Daniel Pospiech has become the company’s documentary memory in terms of production, sales, and safety and an important interface between equipment manufacturing and engineering. He loves the variety in his work and is proud to work at Topas. He has grown closer to the niche industry and the core competence of particle and especially aerosol technology over time. Just as it is necessary for his job. When asked about the most exciting device for him, the future electrical engineer doesn’t need to think long before naming the BBT 143 blow-by test system. Its complexity makes it demanding and thus very interesting for him. The interaction of all the components he made, such as optical and gravimetric measuring systems, controllers, blowers and heaters, or the configuration of various interfaces, was a challenge he was very happy to take on. Despite all the joy of meticulous work, Daniel Pospiech naturally also needs balance after work. Music and programming are two subjects that have inspired him since childhood. Just recently, he developed a metronome with headphone amplifiers and a mixing function. There’s nothing like it yet, but it’s incredibly useful. Working on it relaxed him and the result even helps his band B1000 in the end.