Precise calibration of particle counters and other measuring instruments with mature technology

There are many reasons why instruments are calibrated. Compliance with legal requirements, your promise of quality to customers, or simply the decreasing measurement accuracy of a device are just a few. With our technologies, you can generate customised test and calibration aerosols that you need as a device or aerosol technology manufacturer, as a provider of smart home systems, as a sensor developer, or as a calibration laboratory. As specialists in aerosol generation and conditioning technologies, we develop equipment and test systems that exactly match your specific application.

We are experts in supporting service providers accredited according to ISO 17025 and are pleased to help you. You can find out more about this in the section Calibration of exhaust emission testing devices.

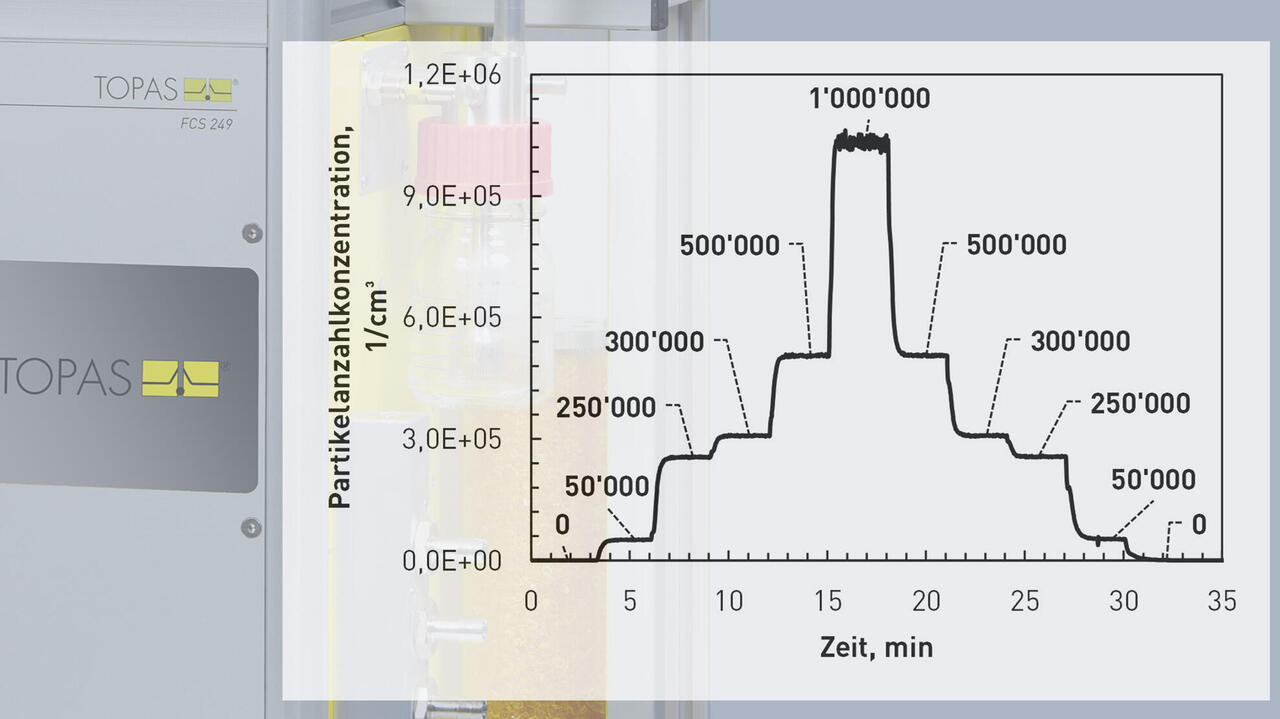

On 20 March, the European Commissionissued a recommendation to improve the regular technical inspection of vehicles (PTI). According to this recommendation, engine exhaust measurements will shift to particle counting methods. The required particle measuring instruments must be calibrated with a reference aerosol that is specified in terms of mean particle size, geometric standard deviation and particle number concentration. Ideally suited for this purpose is the new FCS 249 - a unique calibration system for both condensation core counters (CPC) and electrometers (DC) that are used for PN exhaust measurements. The compact, innovative Topas instrument features aerosol generation and places a special and places a special focus on aerosol conditioning to achieve the required reference aerosol parameters. After a multi-stage development in two years, the compact series device now offers outstanding stability, reproducibility and stability, reproducibility and a set-up time of less than 10 minutes. In compliance with national guidelines, it is an indispensable tool for certification authorities, test service providers and equipment manufacturers. Read more in our data sheet on the calibration of of particle counting devices (PTI) with reference aerosols.

State characteristics of test and calibration aerosols

Depending on the application, test and calibration aerosols with specific properties are required. With our technologies, their characteristics can be specifically realised and modified according to your wishes:

- concentration level: number concentration from a few particles to several trillion particles per cubic metre, mass concentration from nanogram to milligram per cubic metre (with variable-adjustable aerosol generators of the ATM XYZ and SAG XYZ series)

- particle size: from a few nanometres to several micrometres

- substance: salts (NaCl, KCl, …), powders (ASHRAE Test Dust, …) solids (PSL), oils (e.g.: DEHS, PAO, TopFog, Topor, …) as well as biological substances (e.g., viruses, bacteria)

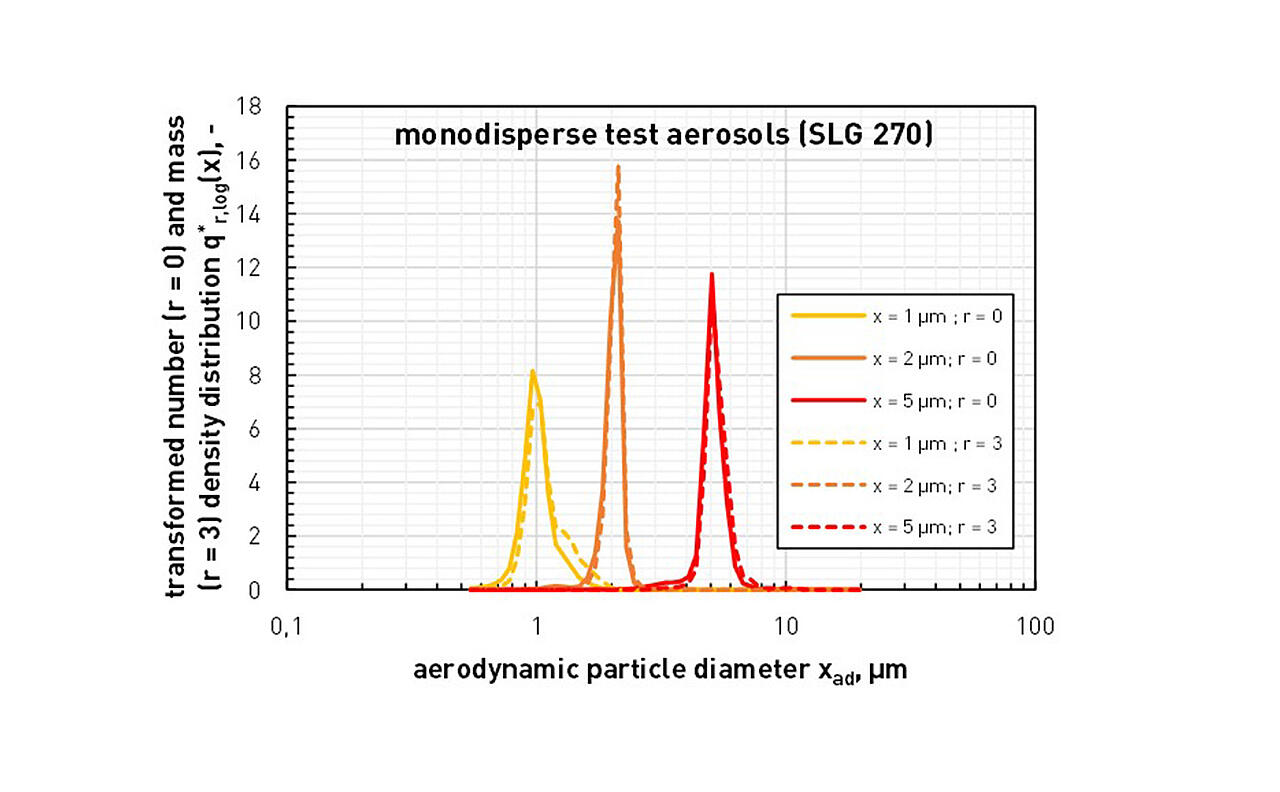

- distribution width: monodisperse (SLG 270), quasi-monodisperse, polydisperse (ATM XYZ)

- modality: monomodal, bimodal or multimodal aerosols (e.g., by targeted use of one or more aerosol generators)

- aerosol charge state: unipolar positive, unipolar negative, or macroscopically neutral (EAN 581 electrical aerosol neutraliser)

Reliable particle counter calibration and validation for various fields of application

- stationary or mobile particle counters, aerosol spectrometers and photometers (SLG 270 Sinclair LaMer aerosol generator, FCS 248 photometer calibration system)

- condensation particle counters (CPC) and electrical aerosol monitors, especially those used for number concentration measurement in exhaust gases according to the AU-Geräte Kalibrierrichtlinie (German exhaust emission test equipment calibration guideline) (FCS 249 mobile field calibration system)

- PM sensors in production (AFC 135 aerosol sensor test system) or in smart home applications (ATM 228 Aerosol Generator)

- smoke detectors (Aerosol Generator ATM 228)

With our technologies for conditioning aerosols, properties can be specifically modulated to calibrate particle counters, aerosol spectrometers, photometers, PM sensors, smoke detectors and much more e.g. according to the ISO 21501 series of standards. The technology used for this is mature, reliable, and precise.

Contact us – we will work out a solution for your specific details.

Calibration of different particle counter technologies

The new version (March 2023) of the "Commission recommendation on particle number measurement for the periodic technical inspection of vehicles equipped with compression ignition engines" describes which particle number measuring devices are to be used for exhaust particle measurement and how they must be calibrated. The guideline mentions single particle measurement for different measuring technologies. These can be condensation particle counters (CPC) or aerosol electrometers (DC). Both provide acceptable measurement results for this application. The guideline also describes the necessary lab and field calibration of particle measuring devices. With its mode of calibration, the FCS 249 field calibration system is suitable for both types of particle counters.

We are experts in the calibration of exhaust gas particle testers. We have listed for whom our turn-key solution is recommended as well as further information under "Calibration of exhaust emission testing device".

The demand for PM sensors is steadily increasing – they are now used in almost all areas of life. Many well-known companies that manufacture PM sensors or use them in their products rely on our technologies.

Mobile phone users can also be excited to learn that the next generation devices will also be equipped with PM sensors.