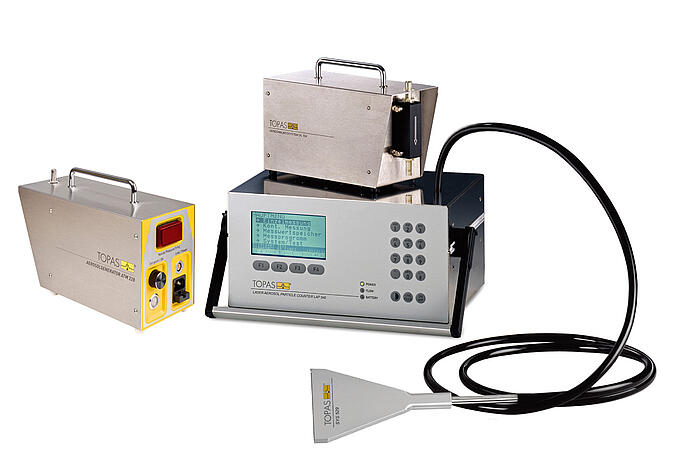

ATM 228 Aerosol Generator

Atomizer Aerosol Generator ATM 228 for aerosol generation from liquids for mobile use, integrated compressor, pneumitic-controlled, remote controllable

The aerosol generator ATM 228 is a further development of the ATM 226 aerosol generator and serves for the mobile generation of test and calibration aerosols from pure liquids, solutions and suspensions. The generator complies to all requirements of VDI 3491-2.

Aerosol generation is realised by a brushless compressor. Accordingly, no external compressed air supply is required. For the purpose of reproducible and long-term stable aerosol generation, the air flow rate is controlled via the pressure drop over the nozzle. This allows also a reproducible and stable generator operation even at very low air flow rates and thus also at lowest particle production rates.

Standards

VDI 3491-2

VDI 4258-1

ISO 14644-3

DIN EN 12469

DIN 12980

ISO 21083-1

Applications

- aerosol generation from pure liquids, solutions and suspensions

- integrity and recovery testing of HEPA/ULPA filters according to ISO 14644-3

- acceptance measurements for clean rooms, safety work benches and smoke detectors

- generation of calibration aerosols (e.g.: for particle counters) at low air flow rates

For the dispersion of the substance to be aerosolised (aerosol substance), the ATM 228 is equipped with a two-substance nozzle designed by the Topas GmbH. The nozzle is operated within or above the aerosol substance (submerged or non-submerged operation mode) and consists of two inlet ports for the supply of air as well as aerosol substance and one outlet port for the generated primary aerosol.

The supply of a defined air flow rate causes a negative pressure at the nozzle inlet port for the aerosol substance. The aerosol substance flows thus into the dispersion zone of the nozzle, where aerosol substance and gas flow converge and form a droplet aerosol.

| Parameter title | Unit | Value |

|---|---|---|

| setting parameter | hPa | differential nozzle pressure |

| setting range | hPa | 0 ... 1400 |

| setting resolution | hPa | 1 (≤ 50), 5 (> 50) |

| setting method | - | manual, controlled |

| aerosol, volumetric flow rate | L/h | 20 ... 250 |

| aerosol, mass flow rate (aerosol substance) | g/h | 0 ... 1,4 |

| operation medium, gas/air | - | ambient air (filtered internally) |

| operation medium, aerosol substance | - | liquids (DEHS, PAO,...), solutions (NaCl, KCl,...), suspensions (PSL,...) |

| operating medium, aerosol substance - filling volume | mL | max. 80 |

| power supply | - | 100 ... 240 V AC, 12 V DC (optional battery operation) |

| hose connector, outlet | mm | Ø 8 |

| power consumption | W | max. 36 |

| environmental condition, max. counterpressure | kPa | 20 |

| dimensions (w × h × d) | mm | 120 × 195 × 300 |

| weight | kg | 3,9 |

- battery connection cable / interface cable

- diffusion dryer (DDU 570/L, DDU 570/H)

- aerosol substance (DEHS, PAO, PSL)

- carry case

- aerosol dilution system (DIL 554), stainless steel, battery operation

- isokinetic rectangular sampling probe (SYS 529) according to EN ISO 14644-3 and VDI 2083-3

- cleanroom particle counter (LAP 340)

- software for cleanroom validation (CRQWin)

- particle instruments interface modul (terminal program)

-

Vasilatou K., Wälchli C., Auderset K., Burtscher H., Hammer T., Giechaskiel B. and Melas A. Effects of the test aerosol on the performance of periodic technical inspection particle counters Journal of Aerosol Science 172 (2023) 0, 1 - 14

dx.doi.org/10.1016/j.jaerosci.2023.106182 -

Knobling B., Franke G., Beike L., Dickhuth T., Knobloch J. K. Reading the score of the air-change in airborne microbial load in contrast to particulate matter during music making International Journal of Environmental Research and Public Health 19 (2022) 16, 1 - 13

dx.doi.org/10.3390/ijerph19169939 -

Weng C.-H., Kao C.-L., Chiu P.-W., Huang S.-P., Kuo Y.-S., Lin Y.-Y., Lin I.-C., Chang H.-C., Lu C.-H., Lin C.-H. A full-face mask for protection against respiratory infections Biomedical Engineering Online 21 (2022) 62, 1 - 16

dx.doi.org/10.1186/s12938-022-01027-1 -

Özyurt O. Methods of classifying aerosol types by using scattering of light 2022 International Conference on INnovations in Intelligent SysTems and Applications (INISTA). 0 (2022) 0, 1 - 6

dx.doi.org/10.1109/INISTA55318.2022.9894146 -

Weng C.-H., Chiu P.-W., Kao C.-L., Lin Y.-Y. and Lin C.-H. Combating COVID-19 during airway management: Validation of a protection tent for containing aerosols and droplets Appl. Sci. 11 (2021) 16, 7245

dx.doi.org/10.3390/app11167245