ATM 240/S Aerosol Generator

Atomizer Aerosol Generator ATM 240/S for aerosol generation from liquids, compressed air operated, high mass flow rate, ideal for KCl aerosols acc. ISO 16890

The aerosol generator ATM 240/S was developed to produce aerosols from suspensions (e.g. salt solutions, sugar solutions) with high quantities of particles > 1 µm.

By operating the generator with aqueous potassium chloride suspensions (> 5 wt.-%), solid aerosols are formed that fulfil the requirements of ISO 16890-2 at moderate test flow rates up to 64 m³/h.

Standards

ISO 16890-2

VDI 3491-2

download

product sheet ATM 240/SApplications

- fractional air filter separation efficiency testing according to ISO 16890-2

- calibration and validation of aerosol-analytical instruments

- medical research on coarse salvia aerosols (mass median aerodynamic diameter MMAD up to 8 µm)

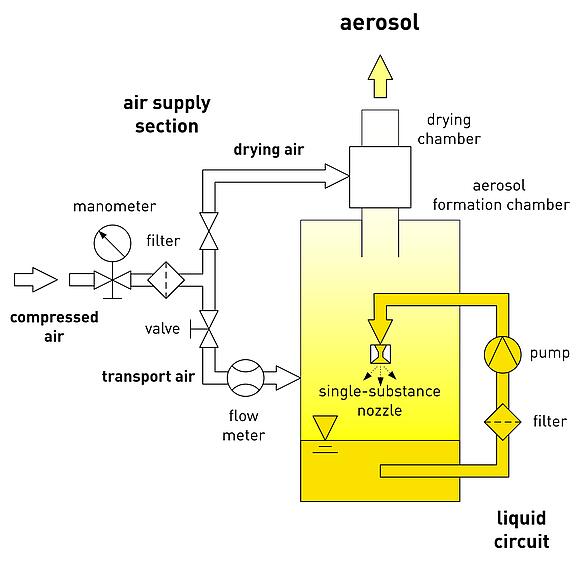

The aqueous suspension to be aerosolised (aerosol substance) is dispersed by a one-substance nozzle within the aerosol formation chamber of the ATM 240/S. The supplied liquid flow disintegrates and forms a broad distributed (polydisperse) droplet aerosol (primary aerosol). Due to inertia and gravitational settling, too large droplets leave immediately the primary aerosol after generation. A dry purge air flow, which is fed into the aerosol formation chamber, transports the remaining airborne droplets into the dip tube and initiates contemporaneous the process of droplet drying. To ensure a drying stable test aerosol, the aerosol passes prior leaving the generator an implemented drying section.

| Parameter title | Unit | Value |

|---|---|---|

| setting parameter | - | aerosol flow rate | relative pump power |

| setting range | - | 218 ... 230 L/h (aerosol flow rate) | 0 ... 100 % (relative pump power) |

| setting resolution | continously adjustable | |

| aerosol, particle size range | µm | 0,01 ... 10 (KCl) |

| operating medium, gas/air | - | dry, particle-free compressed air |

| operating medium, gas/air - compressed air supply | bar | max. 5 (0,5 m³/h) |

| operating medium, aerosol substance | - | solutions (NaCl, KCl, ...) |

| operating medium, aerosol substance - filling volume | mL | 100 ... 300 |

| power supply | - | 110 ... 230 V AC; 50/60 Hz (incl. power adapter 24 V DC, 2 A) |

| hose connector, outlet | mm | Ø 13 (inner diameter) |

| dimensions (w × h × d) | mm | 900 × 400 × 300 |

| weight | kg | 25.0 |