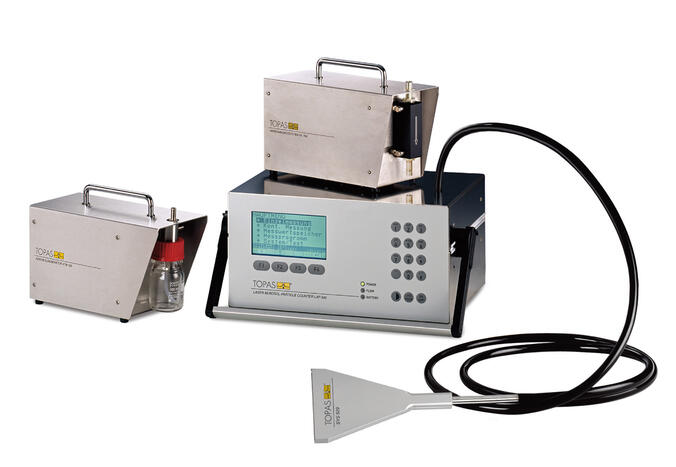

ATM 226 Aerosol Generator

ATM 226 Atomizer Aerosol Generator for aerosol generation from liquids for mobile use (e.g. cleanroom acceptance measurement), integrated compressor

The ATM 226 Atomizer Aerosol Generator is especially suited for clean room and filter testing applications according to international standards.

Such measurements and checkouts need a suitable test aerosol. Therefore VDI-directive 3491 proposes an aerosol generator for producing a test aerosol with defined characteristics, like the ATM 226. By high generated particle numbers at a particle size distribution orientated at the Most Penetration Particle Size (MPPS) of the filter the locating of leaks in the system is possible fast and safe. If an oily aerosol substance is used (e.g. DOP, DEHS) the aerosol generator produces spherical particles mainly in the size range 0,1 … 0,5 µm with a calculable residence time. That does nearly not extra contaminate the filter material.

A further range of application for aerosol generators / liquid aerosol nebulizers is calibration of measuring devices and visualization of currents. That enables measurements of local velocities and flow profiles of the tracer particles by means of optical methods.

Standards

download

product sheet ATM 200 seriesBenefits

- compact stainless steel housing – suitable for clean room application

- connection directly to mains supply

- polydisperse aerosol, mainly < 1 µm

- very high permanence of the generated particle size distribution

- defined and high particle number concentration

- easy handling, designed for mobile use (internal pump)

- connection directly to mains voltage 100-240 VAC

- increased mass output

Applications

- testing of HEPA and ULPA filter media

- acceptance measurements of clean rooms and safety cabinets

- generation of tracer particles at low flow rates

The newly developed atomizer is the key part of the ATM 226 (registered design announcement GS 9408604.4). It is made of high quality stainless steel and works as a two-stream nozzle, based on the injection principle. The unique feature is that the outlet points towards the wall of the glass vessel which works as the baffle plate. This particle impaction section removes coarse spray droplets and results in a particle size distribution mainly below 1 µm. With increasing flow rates the cut point of the impactor is improved, but in the submicrometer range that has only slight influence on the particle size distribution of the aerosol. A low-noise compressor produces the compressed air required for generating the aerosol. The air is cleaned by a HEPA-filter before it is introduced to the atomizer.

| Parameter title | Unit | Value |

|---|---|---|

| setting parameter | - | air flow rate |

| setting range | Skt | 5 ... 40 (scale mark on rotameter) |

| setting resolution | Skt | continously adjustable |

| setting method | - | manuell |

| aerosol, volumetric flow rate | L/h | 70 ... 300 |

| aerosol, mass flow rate (aerosol substance) | g/h | 0,5 ... 2,5 |

| operating medium, gas/air | - | ambient air |

| operating medium, aerosol substance | - | liquids (DEHS, PAO, ...), solutions (NaCl, KCl, ...), suspensions (PSL, ...) |

| operating medium, aerosol substance - filling volume | mL | 20 ... 80 |

| power supply | - | 100 ... 240 AC |

| hose connector | mm | Ø 8 |

| power consumption* | W | max. 36 |

| environmental condition, max. counterpressure | kPa | 20 |

| dimensions (w × h × d) | mm | 120 × 195 × 300 |

| weight | kg | 4,8 |

- aerosol substance DEHS

- diffusion dryer (DDU 570/L, DDU 570/H)

- aerosol dilution system (DIL 554), stainless steel housing, battery operation

- rectangular sampling probe (SYS 529) according to EN ISO 14644-3 and VDI 2083-3

- cleanroom particle counter (LAP 340)

- software for clean room validation (CRQWinⓇ)

- arrying case

- Mishra G., Mandariya A. K., Tripathi S., Mariam, Joshi M., Khan A. and Sapra B. Hygroscopic growth of CsI and CsOH particles in context of nuclear reactor accident research J. Aerosol Sci. 132 (2019) 0, 60 - 69

dx.doi.org/10.1016/j.jaerosci.2019.03.008 - Leskinen A., Yli-Pirilä P., Kuuspalo K., Sippula O., Jalava P., Hirvonen M.-R., Jokiniemi J., Virtanen A., Komppula M. and Lehtinen K. E. J. Characterization and testing of a new environmental chamber. Atmos. Meas. Tech. 8 (2015) 6, 2267-2278

dx.doi.org/10.5194/amt-8-2267-2015 - Anttila T., Brus D., Jaatinen A., Hyvärinen A.-P., Kivekäs N., Romakkaniemi S., Komppula M. and Lihavainen H. Relationships between particles, cloud condensation nuclei and cloud droplet activation during the third Pallas Cloud Experiment Atmos. Chem. Phys. 12 (2012) 23, 11435-11450

dx.doi.org/10.5194/acp-12-11435-2012